Tens of thousands of Gesytec LON Interfaces in the railway engineering industry

LON in railway engineering is a unsung hero. We often know LON from building automation or smart cities. The outstanding properties of LON have made it a robust protocol for many applications in trains for many years. Gesytec has been supplying LON interfaces to this demanding market for over 20 years.

In railway engineering LON is used for many purposes. Lon technology is used in everything from brake systems and display systems to train control systems. Special demands are made on properties such as temperature range, humidity, vibration or electrical robustness. The use of LON is standardized in the IEEE 1473-L. Modularity, robustness, interoperability and outstanding communication properties play an important role. Manufacturers or users such as Bombardier, Alsthom, Ansaldobreda, the New York Metro, Desiro trains in England and others worldwide use LON in trains or for signalling technology. Much trust in the quality of the LON interfaces of Gesytec.

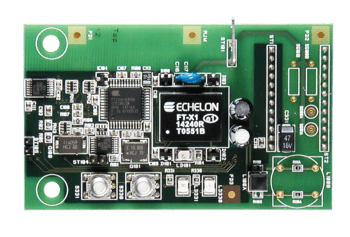

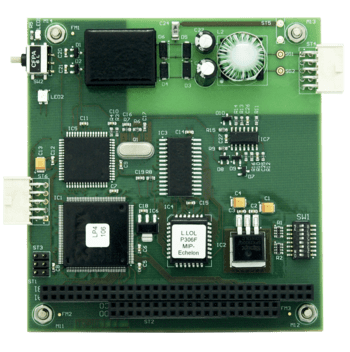

A relevant application is the control and monitoring of pneumatic brakes, in particular of freight trains. In the USA, some freight trains are more than 2 kilometers long. For us as car drivers it is hard to imagine: one part of the train goes uphill, another downhill and these wagons have to be braked. Intelligent brake control optimizes the train’s performance. The control also plays an important role when braking the entire train, the braking distance is decisively shortened. Gesytec Easylon Interfaces are a robust component of the braking systems in the control or monitoring system in the cockpit, e.g. of a Class 66.

Passenger information systems naturally also communicate with the train control system. Interoperability based on LON allows train operators to combine systems from several manufacturers in the vehicle. TFT displays, LCD or LED text displays inform passengers about the next stop, the route or offers at the next station. With LON, the components are interchangeable thanks to a uniform interface. Gesytec supplies LON interfaces for several manufacturers of such systems.

Optimum utilisation of track capacity is of particular interest to operators of underground railways or automated passenger transport systems (PTS, peoplemover). Increasing the capacity of an underground line, for example, may even save the operator the trouble of building a new underground line. With CBTC solutions such as Thales’ SelTrac system, efficiency increases of up to 25% are possible. Gesytec manufactures interfaces that are used in the control computer of a train.

It is not only the special environmental requirements for railway electronics that pose a challenge that Gesytec masters. Highest quality, delivery reliability, long product cycles are demanded by our customers, requirements that we easily meet with our 40 years of experience. Particularly in railway technology, special expectations are placed on long product cycles, long product availability and cooperative life cycle management. A train has a service life of over 40 years. Gesytec provides customers with identical or functionally identical products over decades. Whether it’s a tsunami or just insolvency that causes the end of a factory: Gesytec always finds a solution. Our customers rely on our unique LON know-how for problem analyses and migration strategies. Thus we have customer relationships in railway technology that are almost as old as the LON technology itself.

Gesytec is also working on the future. HD-PLC is a faster transmission technology that can be used both on power lines and on a conventional LON cable, simultaneously with existing use with LON PLC or TP/FT-10. The higher speed of up to 90 Mbit/s with HD-PLC and compatibility with Ethernet can be used, for example, for a migration from simple text displays to screens for passenger information systems without rewiring in a wagon.

Gesytec is also a reliable supplier of reliable LON assemblies for railway applications.