Student research project in electrical engineering with the GesySense T-Checker

Lara Schober, a student from Aachen, programmed a robot in the context of a school project for electrical engineering class so that it can automatically operate the T-Checker from GesySense.

"Since I would like to study computer science later, I wanted to do a project in which I have the possibility to program something," Lara explains the reasons for her series of experiments. After rejecting the idea of designing a vacuum cleaner or a remote-controlled car, Lara thought about the need to check and test the equipment in the industry every day. This idea led to the plan to program a robot in such a way that it takes over this task. The T-Checker from GesySense appeared as a suitable test object for the AL5D-PLTW robot arm. The GesySense® T-Checker is a hand-held device for measuring and recording temperatures that is integrated into the GesySense wireless sensor system.

For example, the T-Checker measures the temperatures of food and compares them with the specified requirement profiles and documents. A profile contains information about the measurement location, the product or test specification, the temperature limits and the evaluation method. The profiles that can be defined by the user are loaded into the device by radio. With the immersion sensor, the T-Checker measures core temperatures from -30 to +100 °C. As part of the student project, the robot arm should switch on the T-Checker, perform two simple temperature measurements and then switch off again.

The aim was to carry out a clear measurement without functional deviations by the robot. The robot should also be able to withstand a real test and relieve the workers from carrying out tests beyond the student project.

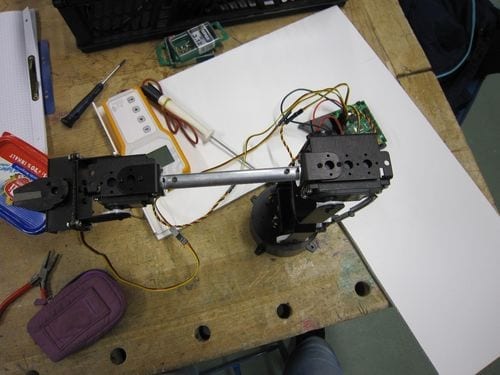

For the test to be successful, the T-Checker must be in a stable position, otherwise new programming would be required for each test procedure. The robot arm was mounted on a suitably sawn wooden plate and the T-Checker was placed in a self-constructed holder so that it has the same position for each measuring process.

To program the robot, Lara has entered the values for the respective motors and set both the position and the speed so that the arm measures the keys at the end in the correct sequence and at the correct speed with a pen for the touch screen.

In the following video Lara explains her project in her own words and shows how the arm and the software operates with the T-Checker from GesySense.

Please turn on the subtitle to understand the video in English.